- Written by sherlley

- Hits: 3588

5 S and work place contd

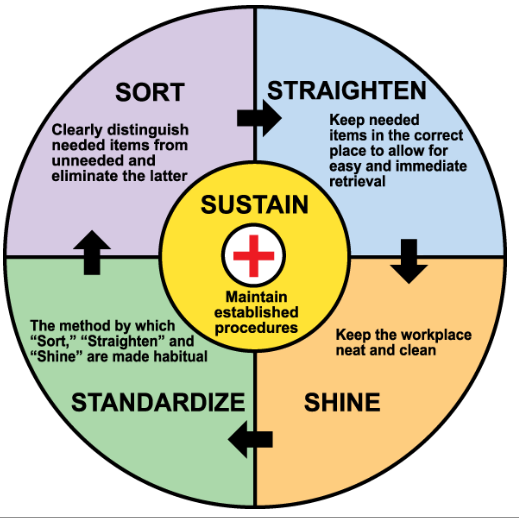

5S is the name of a workplace organization methodology that uses a list of five Japanese words which are seiri, seiton, seiso, seiketsu and shitsuke. Transliterated or translated into English, they all start with the letter "S". The list describes how items are stored and how the new order is maintained. The decision-making process usually comes from a dialogue about standardization which builds a clear understanding among employees of how work should be done. It also instills ownership of the process in each employee.

The 5S's - an English "translation"

1. Seiri : Sort: Clearing the work area

2. Seiton: Set in Order: Designating locations

3. Seiso: Shine: Cleanliness & workplace appearance

4. Seiketsu: Standardize: Everyone doing things the same way

5. Shitsuke: Sustain: Ingraining the 5S's into the culture

The 5S's lead to improved processes and ultimately:

Reduced set-up times

Reduced cycle times

Increased floor space

Lower safety incident/accident rate

Less wasted labor

Better equipment reliability

Sort: Clearing the work area

Any work area should only have the items needed to perform the work in the area. All other items should be cleared (sorted out) from the work area.

Set in Order: Designating locations

Everything in the work area should have a place and everything should be in its place.

Shine: Cleanliness & workplace appearance

Not only should the work area be clear, it should also be clean. Cleanliness involves housekeeping efforts, improving the appearance of the work area, and even more importantly, preventive housekeeping - keeping the work area from getting dirty, rather than just cleaning it up after it becomes dirty.

Standardize: Everyone doing things the same way

Everyone in the work area and in the organization must be involved in the 5S effort, creating best practices and then getting everyone to "copy" those best practices the same way, everywhere, and every time. Work area layouts and storage techniques should be standardized wherever possible.

Sustain: Ingraining the 5S's into the culture

It's tough to keep a 5S effort, or any improvement effort for that matter, going. The 5S's involve a culture change. And to achieve a culture change, it has to be ingrained into the organization - by everyone at all levels in the organization.